Using an artificial intelligence model and 3D printer to create prosthetic eyes reduces the time required to make such implants, which could make them available to more people

By Matthew Sparkes

27 February 2024

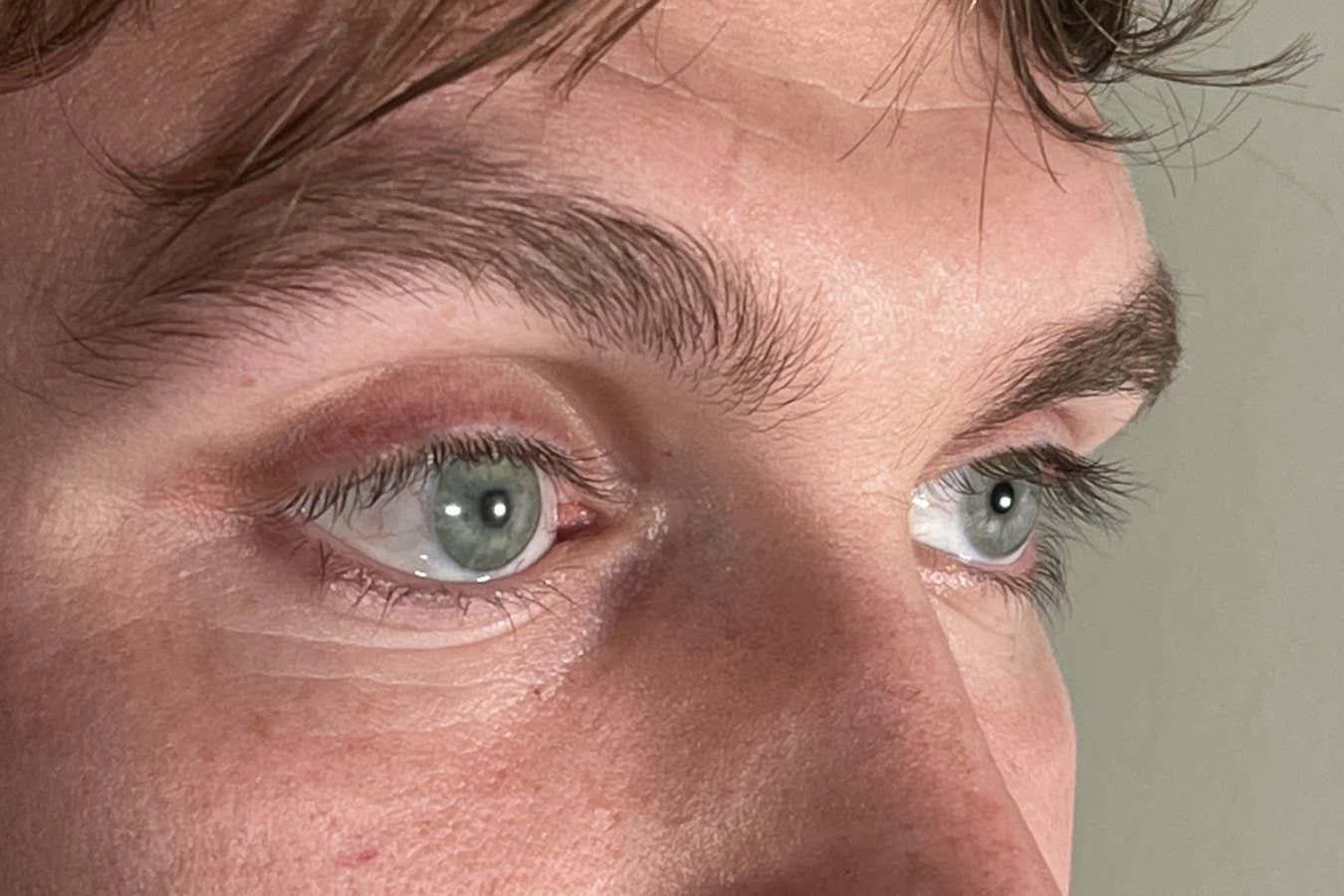

A man with a prosthetic right eye, which was not created via the AI approach

Stephen Bell, Ocupeye Ltd.

Prosthetic eyes that are designed by artificial intelligence and 3D printed require 80 per cent less time from human specialists compared with traditional manufacturing methods, potentially allowing many more people to benefit. A small trial also suggests that this approach leads to well-fitting prosthetics in most cases.

In the UK, for example, around 1 in 1000 people wear prosthetic eyes, which require highly trained ocularists to take moulds of the eye socket. Many people with such prosthetics also have an orbital implant to replace lost eye volume and create a surface to which muscles can be reattached, allowing natural eye movement. Prosthetics sit on top of this to provide a natural appearance.

Read more

How this moment for AI will change society forever (and how it won't)

Advertisement

The standard process of making a prosthetic takes around 8 hours, but now, Johann Reinhard at the Fraunhofer Institute for Computer Graphics Research in Darmstadt, Germany, and his colleagues have developed a method that automatically designs and 3D prints an implant to both fit the wearer’s eye socket and aesthetically match any remaining eye.

“It’s more comfortable to have an optical scan than having someone pouring this alginate [mould-making material] impression into your eye socket, particularly for children – it seems to be tricky to get them to [sit through] this procedure,” says Reinhard.

In the new process, an optical coherence tomography scanner uses light to create a 3D model of a person’s missing eye, so the back of the prosthetic can be designed for a close fit. A colour image is also taken of any remaining eye to make an aesthetic match.